Water

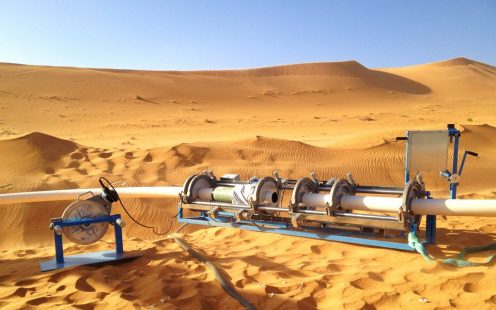

Flexible high-pressure water pipe systems for gas & oil well water injection & disposal

SoluForce offers a range of solutions for water transport & distribution.

Why use SoluForce flexible pipe system?

Featuring polyethylene liners and non-metallic fittings, our high-pressure water pipe systems are durable — they cannot corrode — high quality, fast, and easy to install in overground scenarios or trenches. This makes for an efficient, cost-effective, and long-term solution in water applications.

SoluForce Heavy pipes can withstand very high pressures and are also ideal for high pressure water injection and/or when high-temperature resistance is a priority.

All SoluForce flexible composite pipeline systems are available with non-metallic fittings, couplings, and connectors. Our pipeline systems are therefore resistant to all chemicals involved in oil well water injection applications, including:

- H2S

- CO2

- Strong inorganic acids like HCl and H2SO4

- Strong alkaline materials, including NaOH, KOH, and NH2 solutions

- Anti-corrosion additives

- Mineral salts

Pipe Types

SoluForce Flexible Composite Pipe (FCP, also known as Reinforced Thermoplastic Pipe or RTP) solutions are comprehensive yet economical. For example, you can opt for pipes-and-fittings only or extend this with a range of services and support.

Options include installation equipment for rent or purchase, as well as training of international and local workforces in the use of the SoluForce system. All so you can safely speed up installation and reduce your labor needs. We can also assist you with project management and help find the right people for your project — or any combination of the above.

Because the SoluForce system can be completely non-metallic, including the fitting system, they are both scaling and corrosion free for all water applications. All SoluForce pipe systems have a smooth bore, ensuring a much lower flow resistance and improved flow capacity compared to alternatives. Moreover, their resistance to third-party interference, earthquakes, and landslides has been extensively proven and verified. This makes them ideal to transport water to remote locations.

All SoluForce solutions comply with international standards (including API and ISO). Visit our track record page for more information on various SoluForce applications.

Fitting Solutions

High performance fitting solution, providing reliable connectability. With the electrofusion and single swage fitting solutions, the fluids or gasses never come into contact with the metal parts of the fitting system by using a non-metallic insert. This results in a completely corrosion and scaling free system, no matter what kind of water content is transported through the pipe.

For pressures higher than 150 bar/ 2175 psi, the double swage fitting is the system of choice.

All fittings can be disconnected easily to allow for easy relocation of the pipeline.

Multiple flange ratings are available. All steel parts can be produced according to your material specifications.

Speak To Our Specialists

SoluForce Water Projects

SoluForce aids in the transport of produced water from oil & gas extraction

The majority of oil and gas-bearing reservoirs also contain water. When hydrocarbons are extracted from rock, water also comes to the surface in varying quantities. This byproduct is known as produced water and might also include large volumes of injected water that has been flooded into an unproductive well to increase oil recovery.

Produced water can prove problematic for traditional steel pipes over time, as this byproduct of the extraction process often contains highly corrosive and toxic substances such as chlorides and sulfates — not to mention sodium, which can appear in salinities 15 times higher than seawater.

SoluForce Flexible Composite Pipes contain zero metal — including the fitting systems — so they’re impervious to corrosion and require zero maintenance if correctly installed. Our pipes come in long spools, making them cost-effective and simple to lay, with a working life of 50 years and a CO2 footprint that’s 4 times lower than traditional equivalents.

Frequently Asked Questions

How does water injection in oil wells work?

When oil is recovered from a well in the traditional manner, it is known as primary oil production. When the oil levels in a reservoir become depleted, primary production becomes more resource intensive and less economically viable. Enhanced oil recovery is used to improve the flow of oil from the reservoir and recover more oil than would otherwise be possible from primary production. The same process can also be used in natural gas production.

In most cases, enhanced oil recovery uses water injection to help increase pressure inside the well, allowing more oil to be recovered and increasing dwindling flow rates. Water injection works by drilling a series of extra wells into a reservoir and forcing injection fluid through a high-pressure water pipe, helping to push oil to production facilities where it can then be recovered.

How effective is water injection for oil recovery?

Primary oil production is often only able to recover a maximum of 35% of the oil in a reservoir. At that point, pressure drops, resulting in a reduced production rate. To boost the flow, water injection is used, and depending on the method employed, this can increase the recovery factor dramatically — often allowing another 5-50% of the remaining oil to be pumped from the reservoir.

Why are SoluForce pipes better for water transportation than steel?

SoluForce pipes are entirely corrosion free — including the fittings. This means they are impervious to the strong acid and alkaline substances used in oil and gas recovery methods. Besides that, our pipes are flexible and come in long spools, making them perfect for scenarios where rough terrain or even earthquakes are an issue.

Can SoluForce pipes be used for other water transportation purposes?

In short, yes! SoluForce pipes can be used for any scenario where water needs to be transported safely and efficiently. They are even suitable for drinking water, and have been used for this application. Our pipes have fast install times, and their flexibility makes them ideal for a multitude of applications, from mining to offshore undersea drilling.

Do SoluForce pipes require maintenance?

No. Our high-pressure pipe systems are corrosion free and contain zero metal — including the fittings. If installed correctly, they have a long service life of up to 50 years and will never require welding repairs due to embrittlement.

Get In Touch

Callback