Mining

Corrosion & Abrasion-Resistant Pipe & Long-Life High-Pressure Flexible Mining Pipeline Systems

The unique properties of SoluForce’s abrasion resistant pipe system make it perfectly suitable for ore, mineral, water, chemical, and slurry transport in mining environments.

Why use SoluForce flexible pipe system in mining operations?

Every year, large sums of money are invested in maintaining and replacing damaged mining pipelines. In general, the lifetime of conventional steel pipes is relatively short due to abrasion and corrosion, and they often cannot cope with the challenging environments in which they are installed.

With a strong focus on reliability and sustainability, all SoluForce pipeline components can resist extreme loads while adhering rigidly to the safety standards typically found in mining operations. The SoluForce system is designed for static and dynamic operations and does not suffer from scaling or corrosion, resulting in an extremely reliable, safe and long-term solution.

Due to the flexibility of SoluForce pipe systems, they can easily cope with drastic environmental and climatic challenges, including the stressors inherent to typical mining applications.

The SoluForce system is engineered to resist abrasion from solids and corrosion from fluids transported in mining applications, meaning that the SoluForce system lasts much longer than the alternatives. In fact, when operating within specifications, maintenance work is not needed during the pipe's lifetime (up to 50 years), preventing downtime and saving considerable time and investment.

With pipe lengths of up to 400 meters per coil, the SoluForce system can be delivered and installed quickly and easily with minimal crew and ROW. Add in relatively low cost and short delivery times, and you'll understand why an increasing number of mining operators choose SoluForce as their go-to pipeline solution.

Pipe Types

SoluForce Flexible Composite Pipe (FCP, also known as Reinforced Thermoplastic Pipe or RTP) is comprehensive and economical. For example, you can opt for pipes-and-fittings only, or extend this with a range of services and support. With up to 400 meter of pipe per coil and installation speeds of up to 2 KM a day, SoluForce has proven itself as the go to solution for quick and economical deployment of long lenght pipelines. Furthermore, a minimal ROW and installation crew is required to install the system, which can often be a challenge in the mining industry.

Our additional service include installation equipment for rent or purchase, as well as training of international and local workforces in the use of the SoluForce system to speed up installation and safely reduce your labor requirements. We can also assist with project management and help you find the right people for your mining pipeline project — or any combination of the above.

Because the SoluForce system can be completely non-metallic, including the fitting system, they are scaling and corrosion free. All SoluForce pipe systems have a abbrasion resistant smooth bore, which ensures a much lower flow resistance and improved flow capacity compared to alternatives. Moreover, their resistance to third-party interference, earthquakes, and landslides has been extensively proven and verified.

All SoluForce solutions comply with international standards (including API and ISO). Visit our track record page for more information on various SoluForce applications.

Fitting Solutions

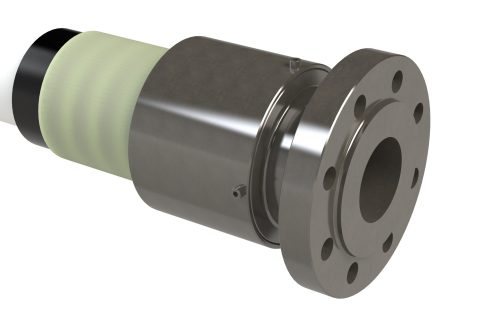

High performance fitting solution, providing reliable connectability. With the electrofusion and single swage fitting solutions, the fluid never come into contact with the metal parts of the fitting system.

For higher pressures or extreme mining operations, the heavy duty double swaged fitting system in combination with SoluForce Heavy is the system of choice. This system is optimized for high axial loads and dynamic operations. Any flange type is possible, connected to the fitting using Grayloc or weld stub.

All fittings can be disconnected quickly to allow for easy relocation of the pipeline.

Multiple flange ratings are available. All steel parts can be produced according to your material specifications.

Speak To Our Specialists

Cases

The Perfect Pipe for Mining Industry Applications

SoluForce pipe systems are resistant to harsh chemicals and corrosion, so they are ideally suited to slurry transport of aggressive materials and even strong acids, salts, and bases. In addition to performing well when handling difficult substances, Soluforce pipes are non-toxic, making them perfect for supplying potable water to mines and in recovery and treatment scenarios.

Unlike their steel equivalents, SoluForce Flexible Composite Pipes are very lightweight, meaning lower transportation costs and less complex installation scenarios — a feature that’s extremely important for mine shafts, where pipework is often mounted overhead.

Finally, when correctly installed, a Reinforced Thermoplastic mining pipeline has a lower risk of static discharges and will cope with the harshest of environments, standing up to intense thermal shock, ground settlement, earthquakes, and other acts of nature.

SoluForce Pipes and the Environment

According to research from the CDP, issues such as flooding and declining water quality pose significant threats to the future growth and success of companies operating in the mining industry. SoluForce’s electrofusion and single swage fittings, combined with long pipe lengths that require fewer joints, mean that our pipes significantly lower the risk of leakages compared to aging concrete or steel installations with weakened weld rings and couplings.

As well as being less prone to leaks from cracking or poorly sealed joints, FCP pipes solutions are completely corrosion and maintenance-free. Ultimately, that means a longer service life and a far lower lifetime CO2 output.

Frequently Asked Questions

What makes SoluForce pipes superior to steel?

Regardless of the different lengths and wall thicknesses of steel pipe, SoluForce Flexible Composite Pipes offer a more practical and economical solution for mining applications. Both mild and carbon steel pipe, as well as induction hardened pipes need to be cut and welded during installation every 12 meters, necessitating flanges, weld rings and other modifications to the wall of the pipe that can compromise integrity — especially in abrasive applications such as slurry pipelines.

Although SoluForce pipes require joints and couplings, they are metal-free and joined by electrofusion, with the pipes available in far longer lengths than steel pipes (up to 400 meters), meaning fewer joints/couplings overall. This makes for greater installation flexibility (especially over long distances) and greater resistance to both external shock and internal abrasion compared to steel pipe systems — not to mention the fact that SoluForce pipes are completely impervious to corrosion.

Can SoluForce pipes be installed anywhere?

SoluForce pipes have been installed in harsh climates and adverse terrain all around the world, from humid jungles to arid deserts. Mining companies have used SoluForce pipe systems for slurry transport of abrasive materials to the top of mountains, in pipe lengths exceeding 1,000 meters each — with install times of just a few days, saving considerable time and money.

Are SoluForce pipe systems cost-effective?

With an operating life of up to 50 years, combined with low susceptibility to abrasive wear, SoluForce pipes require little to no maintenance when correctly installed and operated within the operating parameters. In addition, the long pipe lengths, minimal joints and couplings and flexibility means they can be laid quickly and efficiently even in harsh environments — perfect for slurry pipelines and overhead pipes in mineshafts.

Get In Touch

Callback