Transport oil, gas or corrosive liquids under high pressure over rugged terrain or offshore

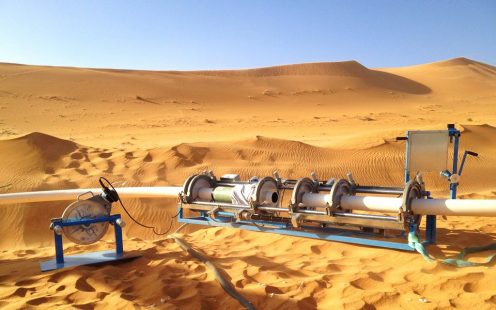

With high strength, supreme flexibility and unmatched performance under high temperatures, SoluForce pipeline systems are simple and quick to deploy, bringing improved efficiency and reduced costs to one of the world’s most demanding industries.

Get In Touch

Transport oil, gas or corrosive liquids under high pressure over rugged terrain or offshore

Extensively field proven

SoluForce was the first ever FCP or RTP pipes to be installed and used in the Middle East back in the year 2000. Since then, over 3,500km of SoluForce pipeline solutions have been installed around the globe. Resulting in an unbeatable track record for many on- and offshore applications including oil and gas utility pipelines, water distribution/ injection lines, oil and gas transportation flow lines, gas and oil gathering lines and domestic hydrocarbon distribution.

The SoluForce system is certified by the world's leading testing bodies. For example, the SoluForce system is developed and manufactured according to the API Q1 and ISO9001 QA/QC Certified Management systems and comply with API 15S (Specification of Spoolable Reinforced Plastic Linepipe) and API 17J (specification for unbonded flexible pipe) for oilfield applications. In addition, the SoluForce system is certified according to multiple local certifications and regulations.

Next level efficiency

Every year, billions of dollars are invested into the pipeline infrastructure of the Middle East alone. Aging pipelines are a huge risk as the assurance of reliable output is vital to oil and gas pipeline operators. Furthermore, making existing or “marginal” oil fields economically viable is a huge challenge while putting a major strain on excisting infrastructure. With increasing risk of spills, most conventional steel pipelines require regular maintenance to extend their lifetime.

SoluForce provides the industry with a pipeline solution that are completely corrosion and maintenance free. That means significantly lower OPEX and TCO compared to alternatives. Moreover, SoluForce installation costs are estimated to be at least 70% lower due to lower weight and availability in longer lengths. Furthermore, the production, transportation, installation, re-use and decommissioning of RTP require less energy, reducing the carbon footprint by at least 75% in comparison with steel pipe alternatives.

Hydrocarbon Pipe System FAQ's

Why choose SoluForce pipe systems for onshore oil and gas?

SoluForce systems have been in use since 2000 across a wide range of applications and in some of the world's harshest environments. Our products are extremely durable and high-quality, meeting or exceeding recognized international standards — perfect for moving highly corrosive liquids and gas under high pressure.

Are SoluForce pipes easy to install?

SoluForce pipe systems are easy to install compared to heavy steel pipes. A small crew can install long pipework lengths quickly and efficiently (up to 2 KM a day), even when working in harsh terrain or with limited space.

Our team of Technical Service Engineers can help with any installation support, even providing equipment such as our electrofusion machine. In addition, we offer training programs to local contractors and engineers through our SoluForce academy.

How are SoluForce pipes joined together?

SoluForce has a range of fitting systems to meet the needs of every application. When transporting corrosive chemicals, non-metallic fittings are used, with joints welded together using Electrofusion.

What applications are SoluForce pipes suitable for?

SoluForce pipe systems can be put to use in a wide range of on- and offshore applications, including oil and gas flow lines, multi-phase pipelines, high-pressure water injection pipelines, gas condensate, oil and gas gathering lines, domestic gas distribution, (jet) fuel transportation, LPG translortation and more. In addition, our flexible pipes can be uncoupled, re-spooled and used again, maximizing value and versatility.

How does SoluForce solve the challenges of steel pips?

There are may advantages to high pressure SoluForce Flexible Composite Pipes compared to steel alternatives, the most important are:

- 100% Corrosion-free

- Fast installation - more than 2 KM a day

- No scaling or corrosion - a smooth bore for a lower flow resistance and improved flow capacity

- Reusable - simply disconnect and load onto our coiling trailer

- Requires zero maintenance-free

- Design life of up to 50 years underground, and a 20 year surface lifespan

- 400-metre lengths per coil - quick delivery and installation of large quantities

- Extremely robust - highly resistant to shock from earthquakes and disruption from landslides or erosion

How does SoluForce compare to other RTP/FCP systems

There are may advantages of the SoluForce system compared to alternatives, the most important are:

- Track record - spanning more than 20 years, with more than 3.500KM installed around the world

- Gas Tight - the only fully Gas Tight high pressure Flexible Composite Pipe available on the market

- Fully bonded - bonded pipe structure providing strenght and reliability

- Fully certified - developed and produced in The Netherlands and fully certified according to multiple industry (and local) standards

- Local presence - worldwide local presence

- SoluForce Academy - train your international staff and deliver local-context training

- Easy installation - easy installation process with 100% traceability and reliable fitting system

- Easy logistics - up to 400 meters per coil and up to 3600 meters on one flat rack

Advanced materials — Unrivaled performance

Deliver hydrocarbons over the next generation of efficient, cost effective flexible pipe systems

Callback